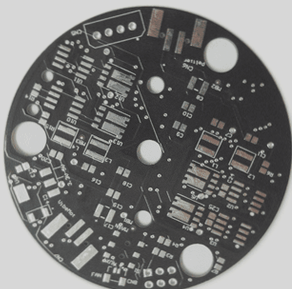

PCBA Processing Technology: Offline vs. Online Burning Methods

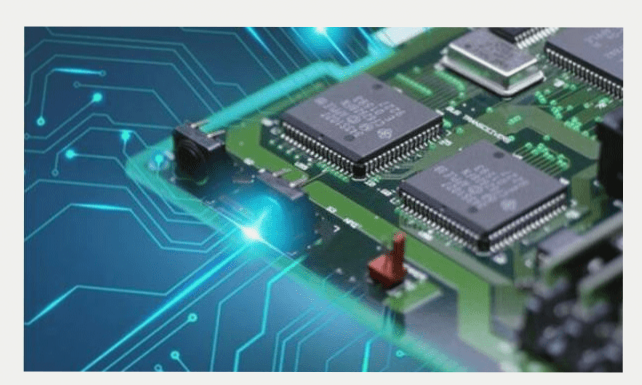

PCBA processing technology has advanced significantly, playing a vital role in today’s intelligent devices. To ensure proper functionality, both hardware and software support are crucial.

Offline Burning

- Offline burning involves programming chips using specific adapters tailored to each chip and package type.

- Commonly used chips like eMMC are moving towards miniaturization and planarization, utilizing formats like BGA and QFN.

- If errors occur during production testing, chips must be removed from the adapter for reprogramming, leading to time and cost implications.

- Issues such as inadequate temperature resistance of circuit boards may cause chip deformation during removal, increasing the risk of scrap.

Online Burning

- Online burning utilizes standard communication buses like USB, SWD, JTAG, and UART for programming.

- With fixed interfaces and fewer connecting pins, online programming reduces power consumption.

- In case of errors during production testing, faulty PCBA can be traced back and reprogrammed without chip disassembly.

- Automation in production lines is increasing, with ICT, FCT, and functional testing machines streamlining processes.

- Automated fixtures and online programming enhance production efficiency by minimizing manual operations.

Online programming in PCBA processing offers significant benefits, improving process accuracy, production efficiency, cost-effectiveness, quality control, scalability, and capital allocation for manufacturers.