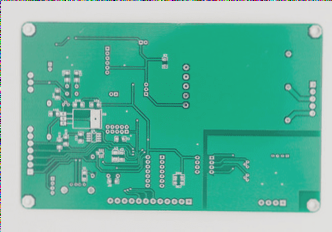

PCB Safety Spacing Considerations

Electrical Safety Distance:

-

Trace Spacing:

When designing a PCB, it is crucial to maintain a minimum trace-to-trace spacing of 4mil to ensure electrical safety. A standard practice is to have a trace spacing of 10mil for optimal performance.

-

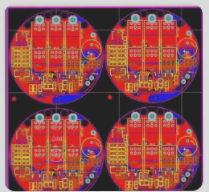

Pad Hole and Pad Width:

For mechanically drilled pad holes, a minimum diameter of 0.2mm is recommended, while laser-drilled holes should have a diameter of at least 4mil. The minimum pad width should also be 0.2mm to meet manufacturing requirements.

-

Pad-to-Pad Distance:

Adjacent pads should have a distance of at least 0.2mm to prevent electrical interference and ensure proper functionality.

-

Copper-to-Board Edge Distance:

Maintaining a clearance of 0.3mm between copper traces and the edge of the PCB is essential to avoid issues like board warping or electrical shorts. Large copper areas should be offset by around 20mil from the board edge.

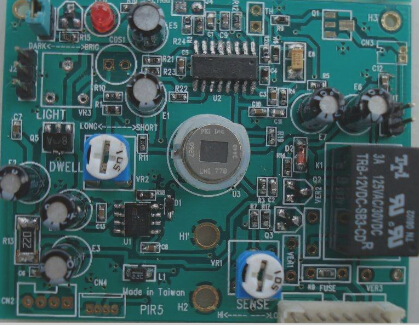

Non-Electrical Safety Distance:

-

Character Width, Height, and Spacing:

Standard sizes for silk screen text, such as 5/30 MIL and 6/36 MIL, are commonly used to ensure clear and legible characters during the manufacturing process.

-

Distance from Silk Screen to Pad:

To prevent issues during soldering, there should be a minimum clearance of 8 mil between the silk screen and the pad. Overlapping can affect component placement, so maintaining proper spacing is crucial.

-

3D Height and Horizontal Spacing in Mechanical Structure:

When placing components on a PCB, it is essential to consider both horizontal and vertical spacing to avoid conflicts with other mechanical structures. Adequate clearance ensures proper fit and functionality within the product enclosure.

If you require PCB manufacturing services or have any inquiries, feel free to contact us.