The Evolution of PCB Industry Automation

Power Feiyang’s Three-Axis Robot Revolutionizes PCB Automation

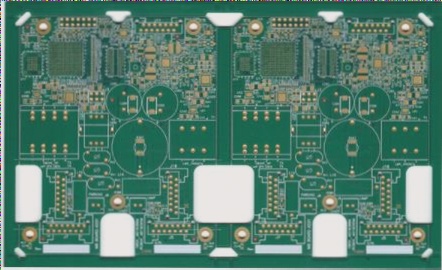

The PCB industry is experiencing a new phase of development driven by the increasing intelligence of mobile phones and automobiles. Market demand is expanding rapidly, pushing PCB manufacturers to embrace automation and smart factory upgrades.

Key Developments in the PCB Industry

- Rising demand for PCB products due to the popularity of smartphones, smart TVs, and 5G technology.

- Advancements in PCB technology, including multi-layering, ultra-thinness, and high precision.

- Global transformation of PCB manufacturing, with China emerging as a major industry player.

The Future of PCB Automation

As the PCB industry evolves, the choice between six-axis, four-axis, or three-axis robots becomes crucial. While more axes may signify sophistication, the practicality of three-axis robots is gaining traction due to their flexibility and cost-effectiveness.

Challenges and Opportunities

With the rapid progress in 5G, autonomous driving, and smart devices, PCB manufacturers must prioritize smart upgrades and automation solutions. Adopting three-axis robotic technology tailored to specific production needs is key to navigating the industry’s transformation successfully.