Understanding the Importance of PCB in Various Industries

Electronic devices have become an integral part of our daily lives, powering everything from our smartphones to our cars. But have you ever wondered how these devices function so efficiently? The answer lies in Printed Circuit Boards (PCBs), which are essential in creating the circuits that drive these devices.

Exploring PCB and Its Diverse Applications

PCB, short for Printed Circuit Board, is a vital component that simplifies the interconnection of electronic components. By eliminating the need for complex wiring, PCBs enhance the efficiency of various devices. Some common uses of PCB include:

- Development of motherboards for phones and computers

- Integration of components in electronic devices

- Creation of circuits for industries like automotive and security

Industries That Rely on PCB Technology

Various industries depend on PCB technology to drive innovation and enhance their products. Let’s delve into some key sectors:

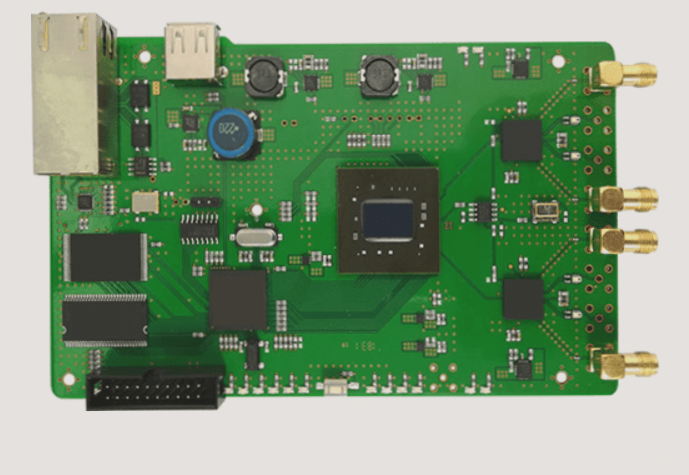

1. Telecommunication and Computing

Telecommunication and computing manufacturers heavily rely on PCBs to create devices that power our digital world. From mobile phones to office equipment like computers and routers, PCBs are essential for seamless connectivity.

- Mobile phones

- Smartwatches

- Computers and laptops

2. Medical Equipment

The healthcare industry has witnessed a transformation with the miniaturization of medical equipment, all made possible by PCB technology. Devices like blood glucose monitors and ultrasonic scanners require PCBs to function effectively.

- Blood Glucose monitors

- Ultrasonic scanners

- Blood pressure monitoring systems

3. Consumer Electronics and LED

Consumer electronics have evolved rapidly, with PCBs driving innovations in residential and commercial lighting, home appliances, and entertainment devices. From smart bulbs to video game consoles, PCBs are the backbone of modern electronics.

- Residential and commercial lighting

- Computer and Television displays

- Video games and consoles

Importance of PCB in Various Industries

PCBs play a crucial role in industries like automotive, aerospace, maritime, and more. These sectors heavily rely on PCB for various applications, such as entertainment units, navigation systems, sensors, and power supply.

- Entertainment units

- Navigation and tracking systems

- Sensors

- Control system and monitoring

- Power supply

- Communication equipment

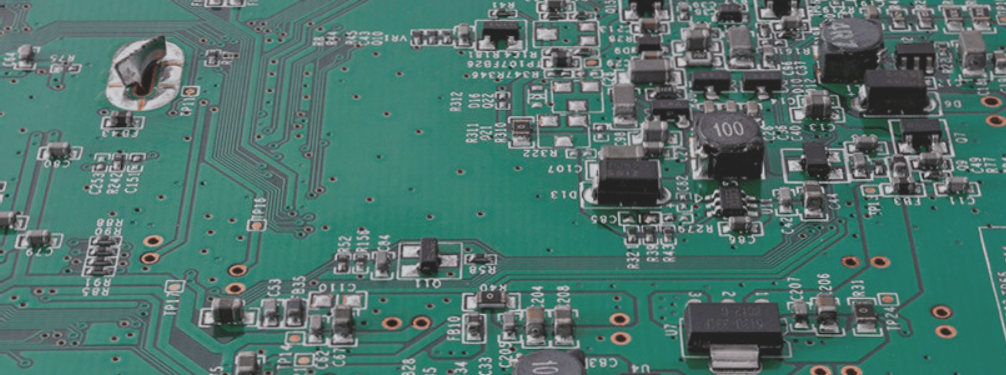

Significance of PCB in Industrial Equipment

PCBs are vital in the industrial sector, ensuring smooth operations in manufacturing, distribution, and storage processes. These durable PCBs are essential for measuring equipment, time management systems, power devices, and robotic sectors within industries.

- Measuring equipment

- Time management and machine controllers

- Power equipment

- Other robotic sectors

Role of PCB in Security Equipment

Security equipment, such as cameras, detectors, and scanners, also heavily rely on PCB for functionality. Companies producing security-related devices like security cameras, motion detectors, and smart alarms require PCB for their products.

- Security camera

- Electric door locks

- Smoke detectors

- Motion detectors

- Secure vaults

- Pass through gates

- Handheld scanners

- Smart alarms

The integration of PCB in security equipment enhances their capabilities, allowing for features like internet connectivity.

Benefits of PCB for Companies

PCB offers numerous advantages for companies, making it an essential component in various industries.

Enhanced Compactness

PCB enables products to achieve compact designs, seen in devices like smartphones, laptops, and medical equipment. In the automotive industry, PCB usage creates space for additional components and features.

Cost Savings

Opting for PCB results in cost savings by eliminating the need for companies to print their circuits. This approach conserves wiring materials, further reducing expenses.

Easy Diagnosing and Repairing

PCBs facilitate easy diagnosing and repair processes, simplifying maintenance tasks compared to traditional wiring methods.

Companies across various sectors benefit from incorporating PCB into their products, ensuring efficiency and innovation.

Simplifying Circuit Understanding with PCB

PCB usage simplifies the reading and understanding of circuits, making diagnosis and repairs a straightforward process. This is particularly advantageous when dealing with complex circuits.

Time Efficiency with PCB Implementation

PCB implementation saves significant time compared to manually wiring components. For instance, in a scenario where a machine places and connects components, the assembly process becomes much quicker, taking only a few seconds to complete.

Enhanced Safety and Reliability with PCBs

PCBs offer improved safety and reliability by providing tighter and stronger connections, reducing the risk of short circuits, and making products more resistant to movement and jittering.

Minimizing Electrical Noise through PCBs

Dealing with electrical noise can be challenging in circuit design. PCBs with efficient designs help reduce electromagnetic interference between points, leading to better stability and decreased electric noise, solving potential design failures.

Final Thoughts

Exploring the extensive scope of PCB reveals its significance across various industries. Understanding why companies should opt for PCB over alternatives is crucial for maximizing efficiency and reliability.

Seeking a Reliable PCB Supplier?

Shenzhen WellCircuits Technology Co., Ltd., established in 1999, specializes in high-quality PCBA orders, catering to diverse needs efficiently. As a comprehensive PCBA manufacturer, we offer services including PCB design, manufacturing, assembly, DFMA service, component procurement, and test assembly. Contact us for your PCB requirements.