Flexible Manufacturing: Meeting the Demands of Individualized Production

As consumer preferences shift towards personalized products, traditional mass production methods are giving way to flexible manufacturing models. These models prioritize responsiveness and customization, catering to a diverse range of offerings in small batch sizes.

The Flexibility of FPC Manufacturing

Flexible manufacturing excels in two key dimensions:

- Production Capacity Flexibility: Machinery and equipment are adept at handling small batch production, ensuring high equipment utilization rates and productivity while keeping unit costs low.

- Supply Chain Agility: The supply chain system is designed to meet individual production and distribution demands, shifting towards a consumer-driven approach.

Key Aspects of Flexible Manufacturing

Flexible manufacturing systems exhibit flexibility in various dimensions:

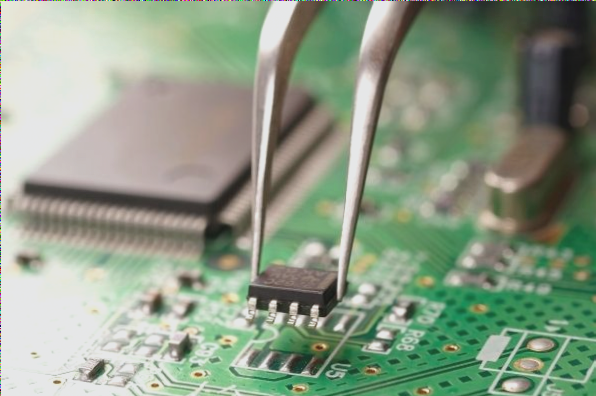

- Equipment Flexibility: Machines can adapt to process different parts as product types change.

- Process Flexibility: Ability to utilize various materials for manufacturing specific parts or products.

- Product Flexibility: Conditions allowing for changes in production economics and speed.

- Work and Rest Flexibility: Managing failures and continuing production using alternative methods.

- Production Capacity Flexibility: Maintaining profitability across different production volumes.

- Expansion Flexibility: Potential for modular, gradual expansion.

- Production Flexibility: Range of part or product types the system can produce.

Current Flexible Manufacturing Technologies

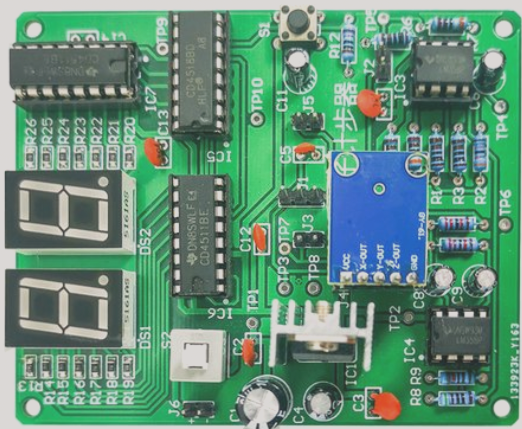

1. Flexible Manufacturing System (FMS): A network of fully automated CNC machine tools connected by centralized control systems, enabling the processing and management of diverse product varieties in small to medium batches.

2. Flexible Manufacturing Cell (FMC): Comprising machining centers, industrial robots, CNC tools, and material transport systems, FMC offers flexibility in processing a variety of products to meet evolving demands.

Flexible Manufacturing Line (FML)

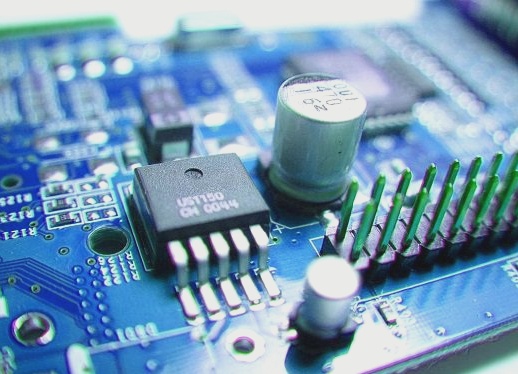

The Flexible Manufacturing Line (FML) acts as a connection between single or small-variety high-volume non-flexible automatic lines and small to medium-volume multi-variety Flexible Manufacturing Systems (FMS). It utilizes general machining centers, CNC machine tools, and specialized machines for processing. While the material handling system is not as flexible as that of FMS, it offers increased productivity. The hallmark of FML is the combination of flexibility and automation in the production line.

Flexible Manufacturing Plant (FMF)

The Flexible Manufacturing Plant (FMF) integrates multiple Flexible Manufacturing Systems (FMS) with an automated three-dimensional warehouse and a computer system. This comprehensive system covers ordering, design, processing, assembly, inspection, and delivery. FMF incorporates CAD/CAM and implements a computer-integrated manufacturing system (CIMS) to achieve flexibility and automation throughout the production process, including management, product processing, and material storage and transport. FMF represents the epitome of automated production, showcasing the most advanced automated application technologies globally. It seamlessly connects manufacturing automation, product development, and operational management, exemplified by the Intelligent Manufacturing System (IMS) that oversees material and information flow, ultimately achieving factory flexibility and automation.