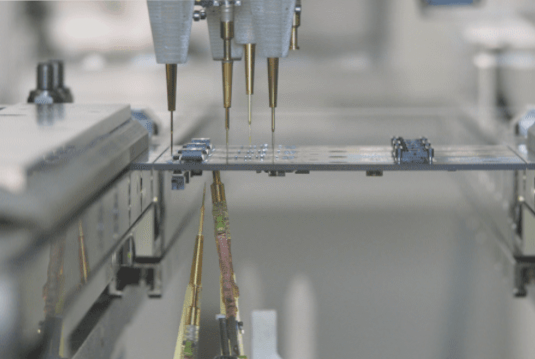

PCBA processing can encounter various challenges during production. For instance, we have previously dealt with defective batches and repairs that went unreported. The initial PCBA processing is essential for the upcoming batch; this entails a thorough inspection and testing of the first PCBA board before full-scale production begins. The first article inspection aims to evaluate, confirm, and test the first product.

The primary goal of the initial PCBA inspection is to identify issues that may impact product quality during the production phase, thereby preventing batch defects or scrap. The first piece of SMT patch serves as a crucial method to proactively manage the production process, while also ensuring product quality. This step is an effective and necessary measure for companies to guarantee product quality and enhance economic efficiency. It is a vital link in the processing chain.

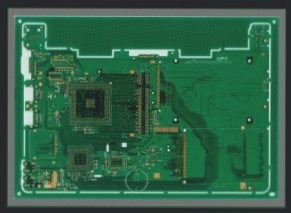

1. Data requirements for the first inspection of PCBA processing.

1. First, the production, engineering, and quality departments must verify the accuracy of the information, ensuring that there are valid samples to reference, including physical samples provided by the customer. This includes product drawings, process documents, BOM, PCBA items, and technical documents outlining special process requirements. Any discrepancies must be addressed with the customer for confirmation.

2. Key aspects of the first inspection in PCBA processing:

a. The initial piece in the order, specifically the first board and first panel, typically consists of two panels: one for SMT modeling and the other for functional testing and full-function verification.

b. When production starts or shifts, the aim of the first panel produced is to check quality and prevent errors from being carried over into subsequent shifts.

c. For ECN changes, such as replacing more than 15 components, a new glue board must be applied for quality measurement, allowing the first piece test to occur concurrently with production, ensuring efficiency remains intact.

d. Process modifications, such as program re-optimization or changes in stations, require re-pasting cardboard for quality assessment. The first piece test can similarly occur alongside production without compromising efficiency.

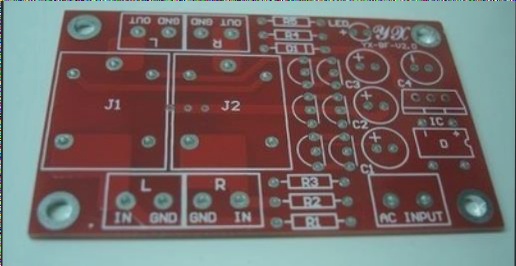

3. Considerations for the first inspection of PCBA processing:

a. Implement protective measures, such as electrostatic protection, ensuring information accuracy.

b. Verify that the position, polarity, angle, and other parameters of the mounted components comply with the technical documents.

c. Assess whether the incoming components meet quality standards, including component color, size, and polarity.

d. Confirm that the soldering quality of components aligns with customer requirements or relevant technical documentation.

e. Inspectors must mark the first piece that passes inspection according to regulations, retaining it until the entire product batch is complete.

f. Timeliness in first article inspection is crucial to maintain production efficiency.

g. If the first piece fails inspection, no further processing or operations are permitted.

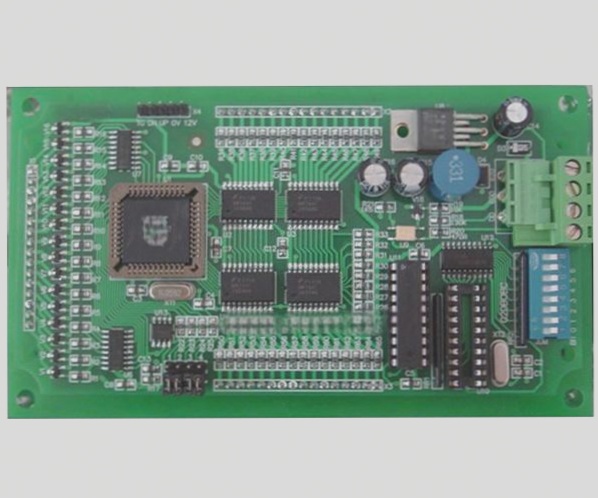

4. Interlocking mechanism for the first inspection of PCBA processing:

a. Self-inspection: Engineers perform self-inspections on the first product, primarily led by on-site engineers, focusing on component orientation and placement effectiveness based on confirmed information.

b. Mutual inspection: After the engineer’s review, the operator conducts a mutual inspection, checking BOM and drawings for material shortages and promptly notifying the production engineer of any discrepancies.

c. Full inspection: Once qualified, the product is sent for a comprehensive inspection by quality inspectors, typically using multimeters or ECR bridges, with large factories mainly utilizing bridges. Key focuses include component measurement and orientation, and for BGA devices, X-ray inspection is required to assess soldering quality. The inspection follows the customer’s original BOM, special processing requirements, and samples to ensure compliance with customer needs and production technical documents, ultimately verifying mass production readiness. PCBA samples passing the “three inspections” are retained until batch production concludes.

d. The foundation of the three-inspection system is the first piece, with its comparison standard being the sample and guidance documents agreed upon by the factory and customer in advance. The accuracy of the sample encompasses both material correctness and soldering precision. In cases of inconsistency between customer guidance documents and samples, the document prevails; if absent, the sample takes precedence. This fundamental principle serves as a safeguard for both the foundry and the customer, aiming to ensure and enhance product quality while minimizing potential losses arising from misunderstandings between parties.

The primary goal of the initial PCBA inspection is to identify issues that may impact product quality during the production phase, thereby preventing batch defects or scrap. The first piece of SMT patch serves as a crucial method to proactively manage the production process, while also ensuring product quality. This step is an effective and necessary measure for companies to guarantee product quality and enhance economic efficiency. It is a vital link in the processing chain.

1. Data requirements for the first inspection of PCBA processing.

1. First, the production, engineering, and quality departments must verify the accuracy of the information, ensuring that there are valid samples to reference, including physical samples provided by the customer. This includes product drawings, process documents, BOM, PCBA items, and technical documents outlining special process requirements. Any discrepancies must be addressed with the customer for confirmation.

2. Key aspects of the first inspection in PCBA processing:

a. The initial piece in the order, specifically the first board and first panel, typically consists of two panels: one for SMT modeling and the other for functional testing and full-function verification.

b. When production starts or shifts, the aim of the first panel produced is to check quality and prevent errors from being carried over into subsequent shifts.

c. For ECN changes, such as replacing more than 15 components, a new glue board must be applied for quality measurement, allowing the first piece test to occur concurrently with production, ensuring efficiency remains intact.

d. Process modifications, such as program re-optimization or changes in stations, require re-pasting cardboard for quality assessment. The first piece test can similarly occur alongside production without compromising efficiency.

3. Considerations for the first inspection of PCBA processing:

a. Implement protective measures, such as electrostatic protection, ensuring information accuracy.

b. Verify that the position, polarity, angle, and other parameters of the mounted components comply with the technical documents.

c. Assess whether the incoming components meet quality standards, including component color, size, and polarity.

d. Confirm that the soldering quality of components aligns with customer requirements or relevant technical documentation.

e. Inspectors must mark the first piece that passes inspection according to regulations, retaining it until the entire product batch is complete.

f. Timeliness in first article inspection is crucial to maintain production efficiency.

g. If the first piece fails inspection, no further processing or operations are permitted.

4. Interlocking mechanism for the first inspection of PCBA processing:

a. Self-inspection: Engineers perform self-inspections on the first product, primarily led by on-site engineers, focusing on component orientation and placement effectiveness based on confirmed information.

b. Mutual inspection: After the engineer’s review, the operator conducts a mutual inspection, checking BOM and drawings for material shortages and promptly notifying the production engineer of any discrepancies.

c. Full inspection: Once qualified, the product is sent for a comprehensive inspection by quality inspectors, typically using multimeters or ECR bridges, with large factories mainly utilizing bridges. Key focuses include component measurement and orientation, and for BGA devices, X-ray inspection is required to assess soldering quality. The inspection follows the customer’s original BOM, special processing requirements, and samples to ensure compliance with customer needs and production technical documents, ultimately verifying mass production readiness. PCBA samples passing the “three inspections” are retained until batch production concludes.

d. The foundation of the three-inspection system is the first piece, with its comparison standard being the sample and guidance documents agreed upon by the factory and customer in advance. The accuracy of the sample encompasses both material correctness and soldering precision. In cases of inconsistency between customer guidance documents and samples, the document prevails; if absent, the sample takes precedence. This fundamental principle serves as a safeguard for both the foundry and the customer, aiming to ensure and enhance product quality while minimizing potential losses arising from misunderstandings between parties.