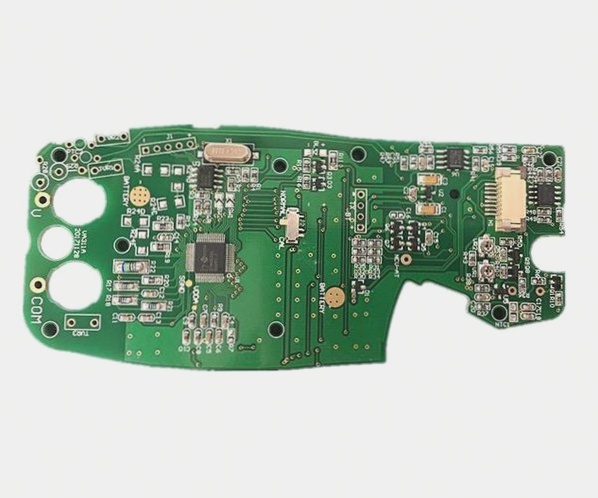

Bluetooth Headset PCBA Processing

Bluetooth Headset PCBA Function Overview

- Ultra-high sensitivity acceptance at -94 dBm;

- Ultra-low power consumption at 10 mA (the 45 mAh lithium battery provides over 4 hours of playback);

- True Bluetooth 5.0 technology;

- Binaural stereo calling with 24-bit DAC/ADC;

- Superior sound quality;

- Easy pairing (automatically powers on when removed from the charging case);

- Over-the-air (OTA) upgrades;

- Exclusive Realtek technology for noise and echo cancellation.

Bluetooth Headset PCBA Processing Steps

- Customers place orders based on their specific needs, reaching out to PCBA processing plants with particular requirements. The processing plant assesses its capabilities to determine if it can fulfill the order. If the manufacturer confirms it can meet the timeline, both parties will negotiate the production details.

- Customers provide production materials. Once the order is confirmed, the customer supplies a range of documents and lists to the PCBA processing factory, including necessary PCB electronic files, coordinate files, and BOM lists, which are essential for production.

- Procurement of raw materials. PCBA processing plants source the relevant raw materials from approved suppliers based on the documents provided by the customers.

- Incoming Material Inspection. Prior to PCBA processing, all raw materials undergo rigorous quality inspections to ensure they meet the required standards before production begins.

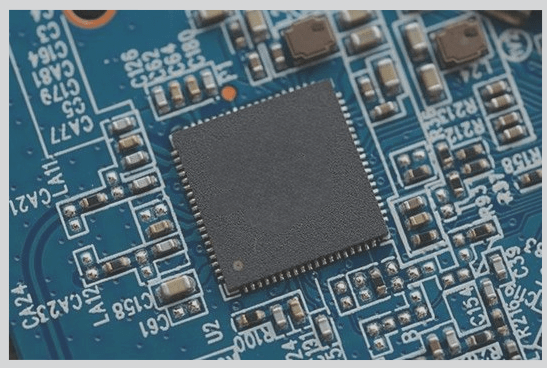

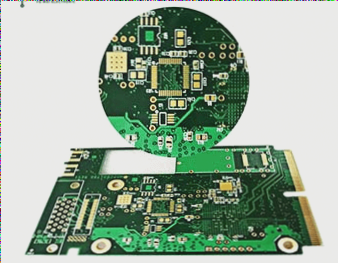

- PCBA production. During the PCBA processing phase, to maintain production quality, manufacturers must strictly monitor furnace temperatures, whether for surface mount or solder processes.

- PCBA test. The PCBA processing plant performs thorough product testing, ensuring that only PCB boards that pass these tests are delivered to the customer.

- Packaging after sale. Once PCBA processing is finalized, the product is packaged and subsequently delivered to the customer, completing the entire PCBA processing workflow.

Bluetooth headset PCBA processing requires specific information:

- Comprehensive PCB manufacturing documents (Gerber files, placement diagrams, and stencil files) along with board fabrication requirements;

- A complete BOM (including model, brand, package, description, etc.);

- PCBA assembly drawings.

Note: To report the PCBA function test fee, the testing method must be provided.

Bluetooth headset PCBA processing manufacturers

What is the cost of PCBA processing for Bluetooth headsets?

The cost of PCBA processing for Bluetooth headsets includes the PCB board cost, PCB testing fee, PCB engineering fee (for small batches), component purchase cost (typically increases by 5%), SMT/DIP welding fee, PCBA testing fee, assembly engineering fee (applicable for small batches), and special packaging and logistics costs if requested by the customer.

How long does Bluetooth headset PCBA processing take?

The timeline for Bluetooth headset PCBA processing encompasses component procurement and PCB production, SMT patch processing, DIP plug-in processing, PCBA testing, and finished product assembly. Specifically, PCB production typically takes 3-10 days, component procurement can range from 2-15 days, with arrival times for components being somewhat unpredictable. SMT and DIP processes usually take 3-5 days, PCBA testing generally requires 1-3 days, and finished product assembly spans 2-5 days.