1. What fields are multilayer PCB boards generally used in?

Multilayer PCB circuit boards are generally used in communication equipment, medical devices, industrial control, security systems, automotive electronics, aviation, computer peripherals, and other fields. They serve as the “core main force” in these sectors. With the continual enhancement of product functionalities, the circuitry becomes increasingly dense. Consequently, market demands for board quality are escalating, with customers increasingly seeking medium to high TG circuit boards.

2. The uniqueness of multilayer PCBs

Ordinary PCBs may deform and experience other issues under high temperatures, leading to significant declines in mechanical and electrical characteristics and reducing product lifespan. Multilayer PCBs find applications in middle to high-end technological industries, necessitating sheet materials with high stability, chemical resistance, and the ability to withstand high temperatures and humidity. Therefore, multilayer PCB boards should be made from materials with at least TG150 to mitigate external influences and extend product lifespan.

3. Stability and Reliability of High TG PCBs

TG Value: TG represents the maximum temperature at which the plate substrate maintains its integrity. It marks the temperature where the amorphous polymer transitions from a glass state to a high elastic state (rubber state), crucial for PCB stability and reliability. A higher TG value enhances these qualities significantly.

4. Advantages of High TG PCBs:

4.1. High heat resistance minimizes PCB pad floating during infrared reflow soldering and thermal shock.

4.2. Low coefficient of thermal expansion reduces warping due to temperature variations and lowers the risk of copper fractures at hole corners caused by thermal expansion. This is especially beneficial in PCBs with eight or more layers, improving plated through-hole performance compared to lower TG value boards.

4.3. Excellent chemical resistance preserves PCB performance during wet processing and exposure to various chemical solutions.

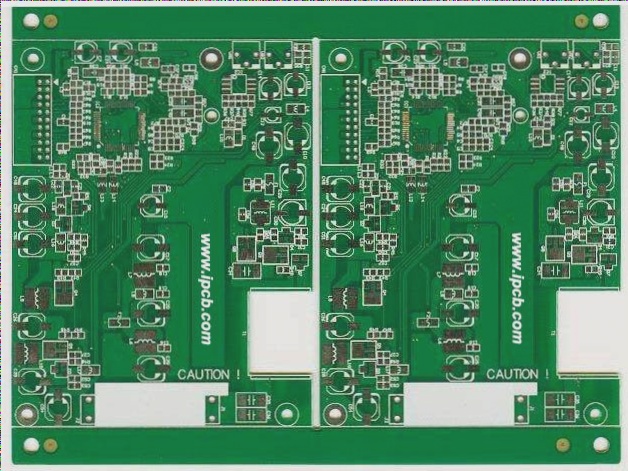

4. High TG PCBs, also known as high-temperature PCBs, undergo a transition from a glass state to a rubber state once a specific temperature threshold is reached. This temperature is referred to as the glass transition temperature (Tg) of the board. Essentially, Tg indicates the highest temperature (in °C) at which the substrate remains rigid. Standard PCB substrates soften, deform, melt, and exhibit reduced mechanical and electrical characteristics under high temperatures. Consequently, product lifespan is adversely affected. Typically, a Tg of over 130°C categorizes a board as medium Tg, while high Tg boards exceed 170°C. PCBs with Tg ≥ 170°C are termed high Tg printed boards. Increasing substrate Tg enhances heat, moisture, chemical, and dimensional stability of the printed board. Higher TG values correlate directly with improved temperature resistance, particularly critical in lead-free processes. High Tg denotes heightened heat resistance, essential as electronic products, particularly computers, evolve toward enhanced functionality and multi-layered complexity. Supported by advances in surface mount technology (SMT) and chip mount technology (CMT), PCBs increasingly rely on substrate heat resistance, accommodating small apertures, fine wiring, and slim profiles.

Multilayer PCB circuit boards are generally used in communication equipment, medical devices, industrial control, security systems, automotive electronics, aviation, computer peripherals, and other fields. They serve as the “core main force” in these sectors. With the continual enhancement of product functionalities, the circuitry becomes increasingly dense. Consequently, market demands for board quality are escalating, with customers increasingly seeking medium to high TG circuit boards.

2. The uniqueness of multilayer PCBs

Ordinary PCBs may deform and experience other issues under high temperatures, leading to significant declines in mechanical and electrical characteristics and reducing product lifespan. Multilayer PCBs find applications in middle to high-end technological industries, necessitating sheet materials with high stability, chemical resistance, and the ability to withstand high temperatures and humidity. Therefore, multilayer PCB boards should be made from materials with at least TG150 to mitigate external influences and extend product lifespan.

3. Stability and Reliability of High TG PCBs

TG Value: TG represents the maximum temperature at which the plate substrate maintains its integrity. It marks the temperature where the amorphous polymer transitions from a glass state to a high elastic state (rubber state), crucial for PCB stability and reliability. A higher TG value enhances these qualities significantly.

4. Advantages of High TG PCBs:

4.1. High heat resistance minimizes PCB pad floating during infrared reflow soldering and thermal shock.

4.2. Low coefficient of thermal expansion reduces warping due to temperature variations and lowers the risk of copper fractures at hole corners caused by thermal expansion. This is especially beneficial in PCBs with eight or more layers, improving plated through-hole performance compared to lower TG value boards.

4.3. Excellent chemical resistance preserves PCB performance during wet processing and exposure to various chemical solutions.

4. High TG PCBs, also known as high-temperature PCBs, undergo a transition from a glass state to a rubber state once a specific temperature threshold is reached. This temperature is referred to as the glass transition temperature (Tg) of the board. Essentially, Tg indicates the highest temperature (in °C) at which the substrate remains rigid. Standard PCB substrates soften, deform, melt, and exhibit reduced mechanical and electrical characteristics under high temperatures. Consequently, product lifespan is adversely affected. Typically, a Tg of over 130°C categorizes a board as medium Tg, while high Tg boards exceed 170°C. PCBs with Tg ≥ 170°C are termed high Tg printed boards. Increasing substrate Tg enhances heat, moisture, chemical, and dimensional stability of the printed board. Higher TG values correlate directly with improved temperature resistance, particularly critical in lead-free processes. High Tg denotes heightened heat resistance, essential as electronic products, particularly computers, evolve toward enhanced functionality and multi-layered complexity. Supported by advances in surface mount technology (SMT) and chip mount technology (CMT), PCBs increasingly rely on substrate heat resistance, accommodating small apertures, fine wiring, and slim profiles.