Understanding Conductive Adhesive and PTH in PCBs

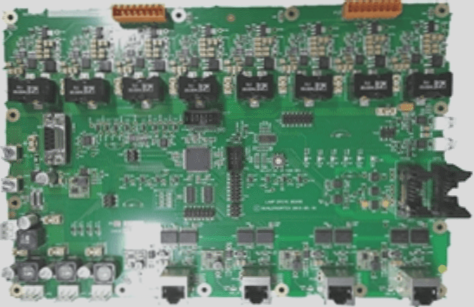

Conductive adhesive is a bonding material with electrical conductivity in its solid state, ideal for creating connections in printed circuit boards (PCBs) without soldering. On the other hand, PTH (Plated Through Hole) technology involves depositing copper layers for interconnections in multi-layer PCBs.

Key Differences Between Conductive Adhesive and PTH

- Cost: Conductive adhesive is more cost-effective than PTH, but cost-cutting measures may impact product quality.

Challenges in Conductive Adhesive Applications

- Initiator Failure: Contamination or mishandling can lead to inadequate bonding strength.

- Resin Matrix Contamination: Pollutants can weaken adhesion and cause circuit failure.

- Inconsistent Mixing: Improper mixing affects curing, resulting in weak bonding and electrical issues.

- Shelf Life: Using adhesives past their shelf life reduces conductivity and adhesion quality.

- Temperature Fluctuations: Storage at varying temperatures can compromise adhesive effectiveness.

- Uncontrolled Cycling: Fluctuating temperatures can degrade adhesive performance over time.

- Process Failures: Improper curing during manufacturing affects performance characteristics.

Conclusion:

Benefits of Using Conductive Adhesives in PCB Manufacturing

Conductive adhesives offer an economical and efficient solution for PCB manufacturing. However, it is crucial to be aware of the potential challenges that may arise:

- Poor bonding strength

- Inadequate conductivity

- Reliability issues during the curing process

Manufacturers must carefully consider the trade-offs between cost savings and product quality. Cutting corners on quality can result in product failures and dissatisfied customers.

Wellcircuits: A Commitment to Quality

At Wellcircuits, we prioritize quality in PCB manufacturing. We have a long-standing commitment to using PTH technology to ensure the reliability of our PCBs. Our goal is to promote the healthy growth of the PCB industry and empower customers to make informed choices when selecting PCB manufacturers.

Cheap PCBs often sacrifice quality, leading to hidden compromises. We are dedicated to delivering top-notch service and welcome feedback from our customers to help us maintain our high standards.

If you have any inquiries about PCBs or PCBA services, please don’t hesitate to reach out to us at info@wellcircuits.com.