PCB Surface Treatment:

Anti-oxidation, tin spraying, lead-free tin spraying, immersion gold, immersion tin, immersion silver, hard gold plating, full board gold plating, gold fingers, nickel palladium gold.

OSP: Low cost, good weldability, harsh storage conditions, short time, environmentally friendly technology, good welding effect, and stable welding.

Spray Tin: The tin plate is generally a multi-sided (4-46 layer) high-precision PCB production template.

Golden Finger: Many large domestic communications, computers, medical equipment, aerospace companies, and scientific research institutions use golden fingers as the connection between the memory module and the memory slot, transmitting all the signals. A gold finger PCB consists of several gold conductive contacts. The surface is gold-plated and the conductive contacts are arranged like fingers, hence the name “golden fingers”. The gold finger is a copper plate coated with a layer of gold through a special process, as gold offers high oxidation resistance and conductivity.

However, due to the high price of gold, tin plating is now more commonly used in memory modules. Since the 1990s, tin has become popular for golden finger PCB production for motherboards, memory cards, and graphics cards. Only some high-performance server/workstation accessory contact points continue to use gold plating due to its higher cost. As integrated circuits become more integrated, IC pins are denser, making vertical tinning processes challenging to create flat pads for SMT placement. Additionally, the shelf life of tin plating is short, whereas gold plating addresses these issues.

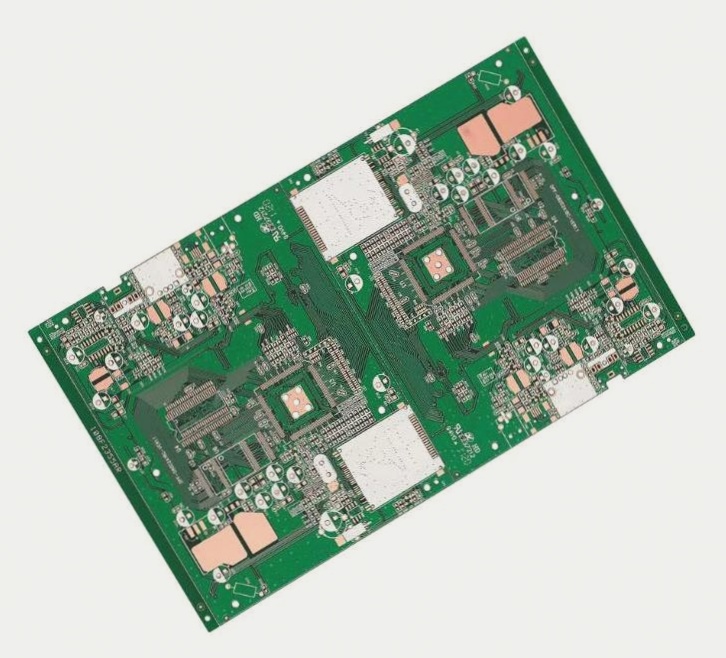

WellCircuits Limited is a manufacturer specializing in high-precision double-sided, multi-sided and impedance, blind buried vias, and thick copper circuit boards. Their product range includes HDI, thick copper, backplanes, rigid-flex combinations, buried capacitance and resistance, goldfinger PCBs, and various other circuit boards to meet customers’ diverse needs.

Anti-oxidation, tin spraying, lead-free tin spraying, immersion gold, immersion tin, immersion silver, hard gold plating, full board gold plating, gold fingers, nickel palladium gold.

OSP: Low cost, good weldability, harsh storage conditions, short time, environmentally friendly technology, good welding effect, and stable welding.

Spray Tin: The tin plate is generally a multi-sided (4-46 layer) high-precision PCB production template.

Golden Finger: Many large domestic communications, computers, medical equipment, aerospace companies, and scientific research institutions use golden fingers as the connection between the memory module and the memory slot, transmitting all the signals. A gold finger PCB consists of several gold conductive contacts. The surface is gold-plated and the conductive contacts are arranged like fingers, hence the name “golden fingers”. The gold finger is a copper plate coated with a layer of gold through a special process, as gold offers high oxidation resistance and conductivity.

However, due to the high price of gold, tin plating is now more commonly used in memory modules. Since the 1990s, tin has become popular for golden finger PCB production for motherboards, memory cards, and graphics cards. Only some high-performance server/workstation accessory contact points continue to use gold plating due to its higher cost. As integrated circuits become more integrated, IC pins are denser, making vertical tinning processes challenging to create flat pads for SMT placement. Additionally, the shelf life of tin plating is short, whereas gold plating addresses these issues.

WellCircuits Limited is a manufacturer specializing in high-precision double-sided, multi-sided and impedance, blind buried vias, and thick copper circuit boards. Their product range includes HDI, thick copper, backplanes, rigid-flex combinations, buried capacitance and resistance, goldfinger PCBs, and various other circuit boards to meet customers’ diverse needs.