Halogen-free materials encompass options such as TUC’s TU883, Isola’s DE156, the GreenSpeed? series, and Shengyi’s S1165/S1165M, S0165, among others.

01

Why is it essential to eliminate halogens in PCB production?

Halogen refers to the group of elements in the periodic table that includes fluorine (F), chlorine (Cl), bromine (Br), and iodine (I). Currently, flame-retardant substrates such as FR4 and CEM-3 predominantly utilize brominated epoxy resins as flame retardants.

Research from relevant institutions has indicated that halogen-containing flame-retardant materials, including Polybrominated Biphenyls (PBB) and Polybrominated Diphenyl Ethers (PBDE), can release dioxins (specifically dioxin TCDD), Benzofuran, and other harmful substances when discarded or incinerated. The resultant smoke is voluminous and unpleasant, containing highly toxic gases that are carcinogenic and can accumulate in the human body, severely impacting health.

Therefore, EU law prohibits the use of six substances, including PBB and PBDE. The Ministry of Information Industry in China mandates that electronic information products released to the market must not contain harmful substances such as lead, mercury, hexavalent chromium, polybrominated biphenyls, or polybrominated diphenyl ethers.

It is understood that PBB and PBDE are virtually no longer utilized in the copper-clad laminate industry. Instead, brominated flame-retardant materials such as tetrabromobisphenol A and dibromophenol are predominantly used. The chemical formula is C12H8Br4. Although this type of bromine-containing copper-clad laminate is not regulated by law, it can emit a significant amount of toxic gases (brominated) and smoke during combustion or electrical fires. Furthermore, when PCBs undergo hot air leveling and component soldering at high temperatures (>200°C), a small amount of hydrogen bromide may be released, with further evaluations needed to determine if additional toxic gases are generated.

In summary, the use of halogens as raw materials has severe negative consequences, necessitating a ban on halogens.

02

**Principle of Halogen-Free Substrates**

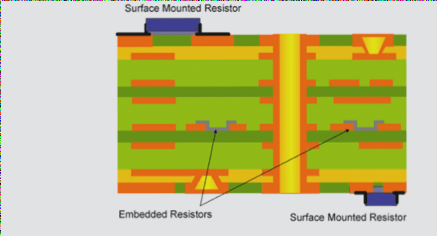

Currently, most halogen-free materials are primarily phosphorus-based or phosphorus-nitrogen-based. When phosphorus-containing resin burns, it decomposes into meta-polyphosphoric acid, which possesses strong dehydration properties. This forms a carbonized film on the resin’s surface, insulating the burning area from air, extinguishing the fire, and providing flame-retardant effects. The polymer resin that includes phosphorus and nitrogen compounds releases incombustible gases when burned, contributing to its flame-retardant characteristics.

03

**Features of Halogen-Free Sheets**

*Material Insulation:*

By replacing halogen atoms with phosphorus or nitrogen, the polarity of the molecular bond segments in epoxy resin is reduced, enhancing insulation resistance and breakdown resistance.

*Water Absorption:*

Halogen-free sheet materials, which have fewer electrons than halogen-based nitrogen-phosphorus reduction resins, exhibit lower probabilities of forming hydrogen bonds with water’s hydrogen atoms. As a result, their water absorption is lower than that of traditional halogen-based flame-retardant materials, positively impacting the reliability and stability of the boards.

*Thermal Stability of PCB Materials:*

Halogen-free sheet materials contain more nitrogen and phosphorus than typical halogen-based materials, resulting in increased monomer molecular weight and Tg values. When heated, their molecular mobility is lower compared to conventional epoxy resins, leading to a relatively smaller coefficient of thermal expansion. Overall, halogen-free boards offer more advantages, making their replacement of halogen-containing boards a general trend.

04

**Experience in Producing Halogen-Free PCB Laminates**

Laminating parameters may vary between companies. For instance, using the aforementioned Shengyi substrate with PP in a multi-layer board requires a lower heating rate (1.0-1.5°C/min) to ensure proper resin flow and bonding strength. This necessitates longer duration at high temperatures, maintaining 180°C for over 50 minutes.

The following outlines a recommended platen program and the actual temperature rise of the plate. The bonding strength between the copper foil and the substrate of the extruded board was 1.0N/mm, and after six thermal shocks, the board showed no signs of delamination or air bubbles.

*Drilling Processability:*

Drilling conditions are crucial as they directly impact the quality of PCB hole walls. Halogen-free copper-clad laminates utilize P and N series functional groups, which increase molecular weight while enhancing the rigidity of the molecular bonds, thus bolstering material stiffness. Moreover, halogen-free materials typically have a higher Tg point than standard copper-clad laminates. Therefore, using regular FR-4 drilling parameters may yield unsatisfactory results, necessitating adjustments during drilling of halogen-free boards.

*Alkali Resistance:*

Halogen-free plates generally exhibit lower alkali resistance compared to standard FR-4. Therefore, during the etching process and post-solder mask rework, it is essential to monitor the immersion time in alkaline stripping solutions to prevent the appearance of white spots on the substrate.

*Halogen-Free Solder Mask Production:*

Currently, many halogen-free solder mask inks are available globally, with performance similar to that of conventional liquid photosensitive inks. The operational procedures are essentially the same as those for standard inks.

Halogen-free PCB boards have low water absorption, comply with environmental protection requirements, and meet quality standards for PCBs, resulting in increased demand for these halogen-free products.