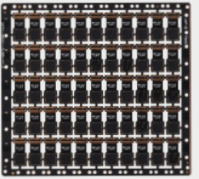

Improving Copper Plating Quality in PCB Fabrication

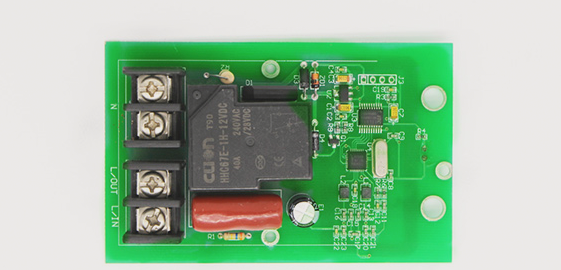

- Using different resin systems and material substrates can significantly affect copper plating quality in PCB fabrication, especially in copper treatment processes.

- Certain CEM composite substrates and high-frequency silver substrates may require special treatment methods for chemical copper plating to achieve satisfactory results.

- Pretreatment of PCB substrates is crucial to avoid issues like poor drilling quality and increased hole count. Baking the material beforehand may be necessary to strengthen the resin.

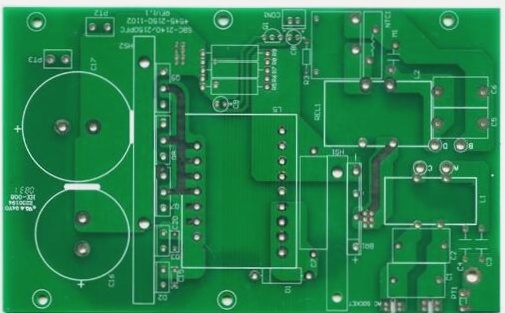

Ensuring Quality in Multi-Layer PCBs

- Inadequate curing in certain areas of multi-layer laminates can impact the drilling process and the removal of rubber slag from active copper.

- Poor drilling conditions can result in issues like resin dust in holes, rough hole walls, burrs, and uneven tear lengths, affecting the quality of chemical copper.

- Mechanical treatment and brushing play a vital role in cleaning surface contamination and removing debris from holes, ensuring proper adhesion and connectivity.

- Effective removal of adhesive slag is essential for hole adhesion and internal connectivity reliability, but improper coordination can lead to quality problems.

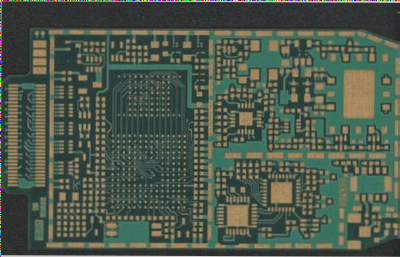

Challenges and Solutions in PCB Production

- Coordinated control of groove fluids is crucial for complete slag removal and preventing defects like resin sinking or hole wall shedding in post-processing stages.

- Excessive adhesive removal can lead to issues like glass fibers protruding from hole walls, compromising bonding strength with chemical copper.

- Controlling the removal process effectively is essential to prevent open circuits and ensure uniform deposition of chemical copper on the substrate.