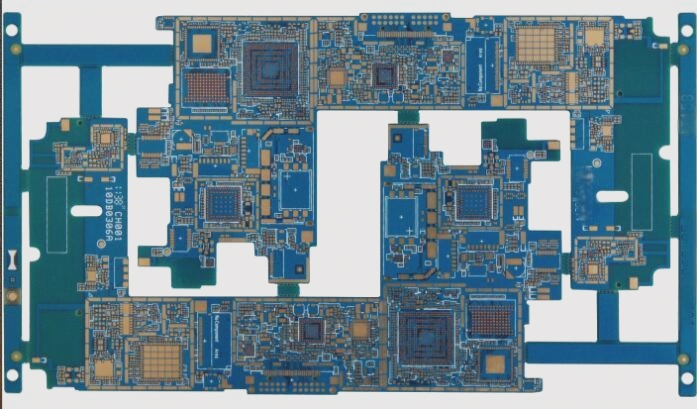

The Importance of Flying Needle Testing in PCB Quality Control

When it comes to proofing PCB circuit boards, the flying needle test plays a critical role in ensuring quality. Unlike traditional needle bed testing, the flying needle test utilizes custom-made probes to examine the PCB circuit board. But what sets these methods apart in terms of accuracy and cost?

Probes in Flying Needle Testers

- Flying needle probes are custom-made, flexible, and easily replaceable.

- Each probe has a lifespan of 1 million cycles and can test 1,000 points.

- With 40 probe heads replaced daily in high-capacity plants, the cost of probe replacement is minimal.

- Flying needle testers offer greater flexibility and interchangeable probe specifications compared to needle beds.

Accuracy and Cost Considerations

- Flying needle testers typically achieve around A4 accuracy with a tolerance of (+) 30 μm on the X, Y, and Z axes.

- Despite potential differences in accuracy, flying needle testing remains highly effective even with smaller components.

Application of PCB Test Stand:

- PCB test stands are suitable for enterprises with single-product, high-speed production needs.

- However, the flying needle test is increasingly popular in both small and large patch processing plants due to market diversification.

- Flying needle testing offers a broader application range and helps shorten product development cycles.

- As components on PCBs shrink, flying needle testing can achieve a 100 μm test, surpassing the limitations of test stands.

- While flying needle testing boasts higher accuracy, it may result in slower production efficiency in some cases.